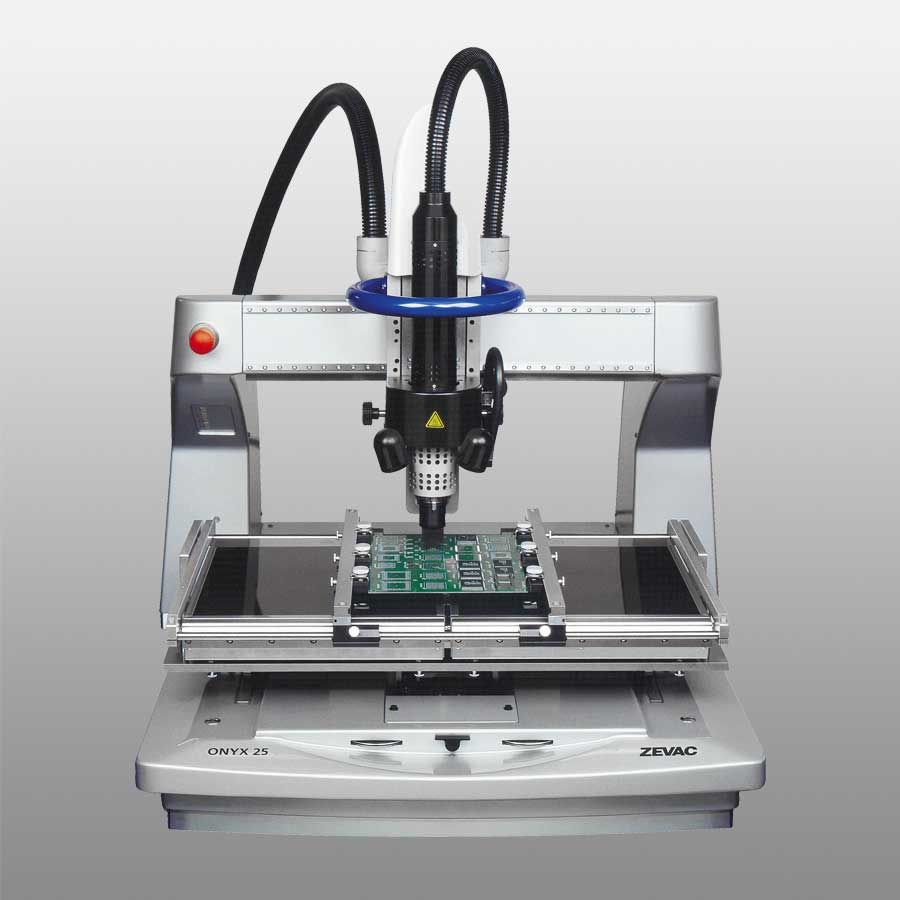

ONYX 25

The ONYX 25 is used to process printed circuit board with a width up to 560 mm and, thanks to the open construction, with an unlimited length. Due to the integrated vision-system the precise orientation of components is guaranteed. The multifunctional hot gas heater head can be used to solder components, to remove components and for site clean processes (contactless removal of residual solder). In addition many unique options for several additional processes are available.

Main Features

- 2000 watt multifunctional hot gas heater head: Solder components, remove components, site clean (contactless removal of rest solder), customer specific application upon request

- Four motorized axes with closed loop motion control

- Integrated hand wheels for quick and precise positioning of the hot gas head

- Automatic process control

- Up to eight thermocouple ports to control process temperature

- Large board handling for boards up to 560 mm width, no limitation for length thanks to the open construction

- Board carrier handles irregular-shaped assemblies without special fixtures

- Bottom pre-heater with a performance of 3500 watt and the dimensions of 300 x 300 mm per module (maximum 2 pre-heaters with a total area of 600 x 300 mm) with integrated board cooling

- Automatic closed loop force control of the Z-axis for automatic picking, fluxing, placing and removing processes to protect sensitive parts

- Closed loop gas flow control from 8 to 80l/min

- The MFOV system allows viewing components with dimensions up to 75 x 75 mm and allows an excellent adjustment of the image contrast

- Semi-automated, contactless site cleaning for the removal of residual solder with a motorized Z-axis

Repair of large circuit boards

Thanks to the high placement accuracy of <10 µm, the integrated force measurement and the control via four motorized axes, reproducible results and highest quality are guaranteed for serial repair and many other applications. Because of the open construction of the ONXX 25 the length of the edited printed circuit boards is not limited. Moreover, due to the movable soldering head the flexible positioning on the X-axis is possible, without moving the printed circuit board.

The open architecture of the ONYX 25 and the variety of closed loop controlled parameters of the application software VisualMachinesTM allow simple lab applications as well as high complex production processes repetitive and extremely precise.

Application Range

Repairs

Misaligned devices can accurately be repositioned and defective components can reliably be replaced.

Prototyping

The components of small and extreme large printed circuit boards can be assembled and soldered with the ONYX 25 semi-automatically. It allows already used expensive components to be re-used.

Post-assembly

Components that are missing at assembly time can be placed and soldered later, or individual components which cannot be handled by the available production machines can be retrofitted with the ONYX 25.

Assembly

When printed circuited boards with only a few components need to be assembled, then the ONYX 25 often can provide a reliable semi-automated solution.

Components

Zevac`s standard gas nozzles from the proven DRS selective soldering machines can be used on the ONYX 25 without any modification. With the ONYX 25 all electronic SMD components and all customer specific components can be handled easily.